|

displacement transducer application in pre test Source:http://www.hawkinkjet.com/News/80.htmlDatetime:2014-07-15 Brief:modern pre-programmed (smart, NC) tensioning technology is based on linear displacement sensor/cable and computer intelligent sensor technology automation measuring and control technology to realize automatic control of tensioning operation. Modern programmable system composed by a program host and job front. Jobs front contain measuring and control circuits, pumps and thousands of top, sensors and other components.

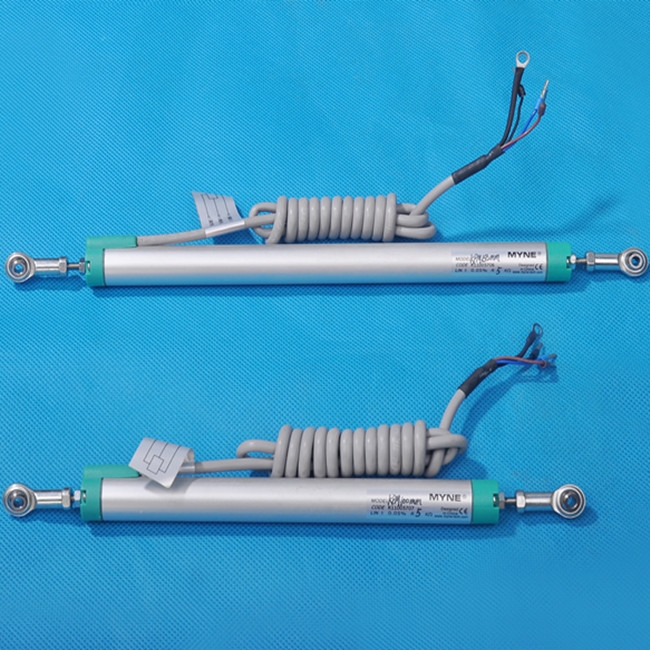

displacement transducer

in understanding of linear displacement sensor/cable sensor in advance prior to the application of testing, you must first understand what is prestressing, prestressing force these two concepts, only by knowing the two concepts in order to understand why this displacement sensor in pre-stressed test applications.

pre is the abbreviation of prestressing, before the structure subjected to external loads, advance on the regional stress under external loads in order to improve the performance of structures using. can be used to resist compressive stress structure subjected to tensile stresses or bending moment, and stress resistance of structures subjected to compressive stress. good based on prestressed theory and technology, makes it possible to improve the structure and effect of improving the bearing capacity of the structure. prestress in action: test schematic

due to the tensioning prestressing construction of traditional job control error, measurement error and retraction value is unmeasurable, ends the synchronization rate too low to achieve the double control of tension and means of control, the lack of reliable and effective means of detection and evaluation of the shortcomings, so it was gradually replaced by intelligent, digital control tension technology. tensioning control system with unstressed master index, elongation as auxiliary control index, real tension and elongation value control, ensure that the elongation in tension at both ends of the unstressed and the whole process is highly synchronous. sync error strictly within the 2011 version, within the scope of the provisions of the technical code for construction of highway bridges and culverts. on pre-stressed tension of the testing process, the instrument can control the oil quantity, put a pressure for precise control, implementation process, speed controllable. the stress measured precisely placed to the beginning of clip back part of the shrinkage cavity and the jacks strand's elastic deformation, which put a strand a valid extension. jacks tensioning control system not be modified measurement system implemented by external ultrasonic sensor can be directly measured the length of the strand, by high frequency extension value monitoring, in real time the pressure value can be in tension-real-time reflecting curves with different values of tensioning force of steel strand, you can directly read the retraction value. MYNE supporting pre-testing products are divided into two categories, is a non-contact displacement sensors is the magnetostrictive displacement sensor, which people usually say magnetic sensors, magnetic sensors, hydraulic cylinder position sensor, split displacement sensors , precision displacement sensor and so on, another contact-type displacement sensor including: linear displacement sensors , the rope displacement transducers , angular displacement sensors, LVDT displacement sensors, pressure sensors, and so on. these displacement sensor everyone usually in daily in the often to its connection way or explicit chopsticks of appearance characteristics respectively called different of name child, as electronic feet, and DrawString coding device, and lever displacement sensor, and DrawString sensor, and DrawString type displacement sensor, and back play type displacement sensor, and since reset displacement sensor, and explosion-proof displacement sensor, and micro displacement sensor, and micro pulled rope displacement sensor and the special displacement sensor etc. all these are in fact used term for various people in various places. 。3 |

| About Cardofcom|Add to Favorites|Register Cardofcom.net|Proposed Feedback|Contact us |

| Cardofcom.net---Card of com at net |

| 版权所有 沧州双一商贸有限公司 冀ICP备16002221号 |