|

法利莱光纤激光切割机助农机制造走向现代化 Source:http://www.hglaser.com/news/22172_for_gongsixinwen_text.htmDatetime:2014-08-13

in recent years, the agricultural machinery industry, the rapid development of modern processing techniques the demand becomes more urgent. the face of agricultural machinery product upgrades and new product development, traditional technologies have been unable to meet the new requirements by way of new processing, CNC and laser processing technology, automation technology, which improve the application of existing technology, will undoubtedly speed up the process of agricultural modernization in our country. for example, agricultural machinery manufacture sheet metal processing parts used in General 2-6mm sheet metal, sheet metal variety, update soon, traditional agricultural products usually used for sheet metal punch, die high cost, usually a large agricultural machinery manufacturer to mold storage warehouses close to 300 square meters. agricultural machinery parts processing if staying in traditional ways, will restrict the rapid replacement of the product and technology development. compared with traditional CNC turret punch press, laser cutting machines for processing advantages are even clearer.

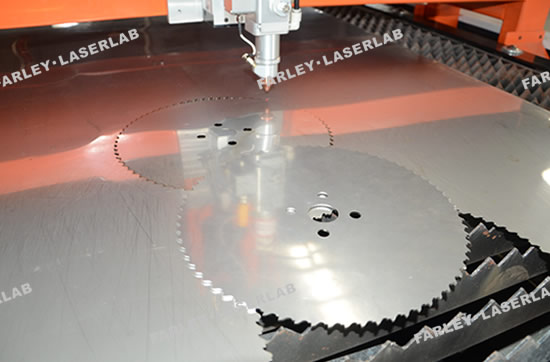

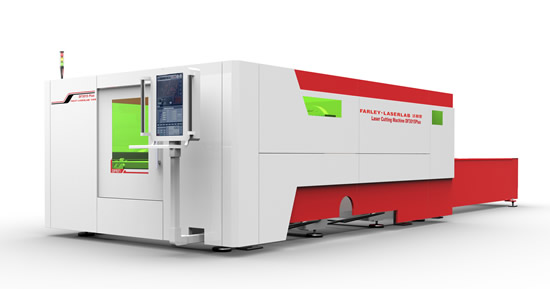

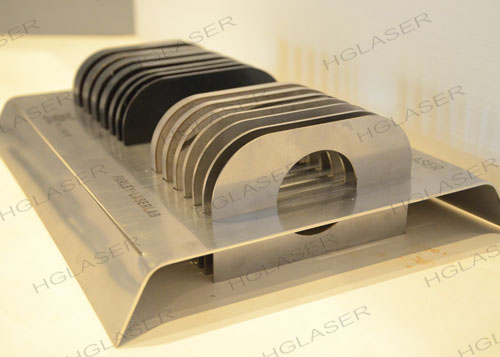

in agricultural machine manufacturing process, major advantages using laser cut metal parts of the process are: 1. laser cut flexible degree high, cutting speed fast, processing efficiency high, products production cycle short, regardless of is simple also is complex parts, are can with laser achieved once fast forming cutting;2. cut sewing narrow, and cutting quality good, and automation degree high, operation simple, human intensity low; 3. can achieved cutting automatically row sample, and sets material, improve has material utilization, no tool wear, material adaptability good; 4. low cost, good economic returns, and pollution-free. laser processing to use specialized software to realize any shape of sheet metal cutting by laser processing to avoid mold or tool change, greatly enriched the original means of processing, but also can effectively shorten the product development cycle and improve agricultural production efficiency, especially for complex parts in new product development advantages of laser cutting. thus, laser machining has become essential in agricultural production and processing methods, promotion of agricultural machinery equipment manufacturing modernization of emerging growth, become important technical support to reform traditional agricultural machinery manufacturing. for agricultural machinery manufacturing industry, huagong laser Farley Lai launched a range of laser cutting machines, to provide users with the most comprehensive range of solutions. FARLEY · LASERLAB DF3015Plus series CNC laser cutting machines equipment Description: DF3015Plus series CNC laser cutting machines, machines used the gantry structure of bilateral driven, synchronous high speed pallet beams, high strength aluminum alloy, Germany CNC systems and precision linear Guide and helical gear rack drive system. with an integrated structural design, the area is less than similar models. the device as a whole has good rigidity, steady performance, high speed, high precision, high efficiency, high value embodiment of. DF3015Plus provides a powerful cutting capabilities, to meet the carbon steel, stainless steel and other metal sheet cutting needs, are ideal for sheet metal processing. sample

cutting material: stainless steel-carbon steel cutting thickness: 1-5mm

cutting material: stainless steel cutting thickness: 2.5mm as the leading brand of laser cutting and welding technology, FARLEY · LASERLAB originated from Australia, global service, huagong laser Farley Lai company research and development and production of laser cutting machines running in over 20 countries, regional stability, market ownership continued for many years ahead.2014 year, China fiber laser cutting market will officially switch to the diffusion, huagong laser falilai will no doubt become a leader in opening time. copyright huagong laser all, reproduced, please indicate the source. |

| About Cardofcom|Add to Favorites|Register Cardofcom.net|Proposed Feedback|Contact us |

| Cardofcom.net---Card of com at net |

| 版权所有 沧州双一商贸有限公司 冀ICP备16002221号 |