|

application of fiber laser cutting machine in the kitchen industry Source:http://www.hglaser.com/news/22192_for_gongsixinwen_text.htmDatetime:2014-08-13 Brief:with the socio-economic development and progress, it is higher requirements for supplies and utensils of daily life. Requirement profile and unique, but also features varied and durable. Traditional processing methods such as Leng Chongqie, cold cutting, shearing, punching and other serious environmental pollution, Burr, subsequent dealing with labour-intensive and time-consuming, can no longer meet the needs of our customers and markets. with the socio-economic development and progress, it is higher requirements for supplies and utensils of daily life. the requirement profile is unique, but also features changeable durable. the traditional processing methods such as Leng Chongqie, cold cutting, shearing, punching and other serious environmental pollution, Burr, subsequent dealing with labour-intensive and time-consuming, can no longer meet the needs of our customers and markets. kitchenware industry as the industry is closely related to people's daily lives and in recent years, is constantly updated and rise. in the kitchen industry, range hoods, ovens, hobs Panel, large commercial kitchen products such as extensive use of sheet metal panels. traditional processes require large amounts of molds, designing and manufacturing cycle time, low efficiency and high cost.

application of laser cutting in the kitchen industry

application of laser cutting in the kitchen industry

application of laser cutting in the kitchen industry environment of intense competition in the market as a whole, needed to adopt new processes and equipment to push industrial development. as the laser industry leader FARLEY · LASERLAB Leroy companies, committed to research and development of advanced laser equipment, and provide authoritative solutions for kitchen industry.

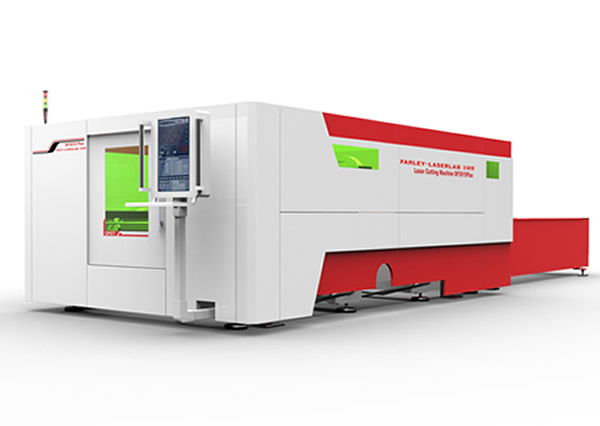

FARLEY•LASERLAB DF3015Plus optical fiber laser cutting machine FARLEY · LASERLAB DF3015Plus CNC laser cutting machine total used gantry structure, high strength aluminum alloys the tensile beams, Germany professional CNC laser cutting systems, precision linear Guide and helical gearing system, machine rigidity, stable performance, stable operation, high speed, high precision and high efficiency. can quickly and efficiently accomplish any graphic one-piece stainless steel cutting of materials, reducing labor costs and improve efficiency, enhance the yield of the kitchen, reduced loss of material. to meet the carbon steel, stainless steel and other metal sheet cutting needs, is the ideal choice for thin sheet metal processing. DF3015Plus the following highlights advantages of single-axis positioning speed 80m/min acceleration 1.5G, General processing methods can solve the time-consuming problemsdual synchronous AC servo motor drive system; Germany imported BECKHOFF control system, with special functions for laser cutting; high precision reducer, high precision grinding of helical gears and rack to ensure kitchen with the high quality and high precision; simple and stylish appearance, centralized lubrication system, and exhaust, runs no discharges of hazardous substances; rapid synchronous exchange workstations, to increase my productivity. appreciate DF3015Plus details

DF3015Plus dedicated fiber laser head

electrical box empty

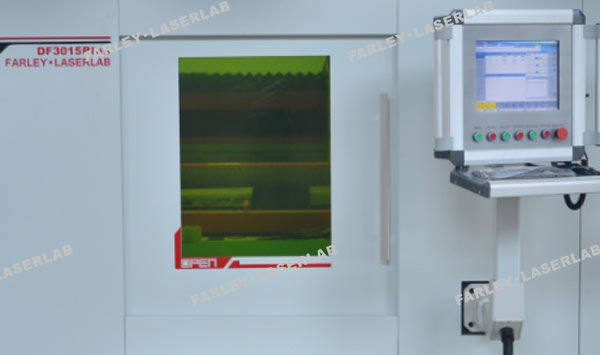

NC system platform

high precision grinding of helical gears and precision linear Guide

table remote switching system

laser protective glasses to protect eyes

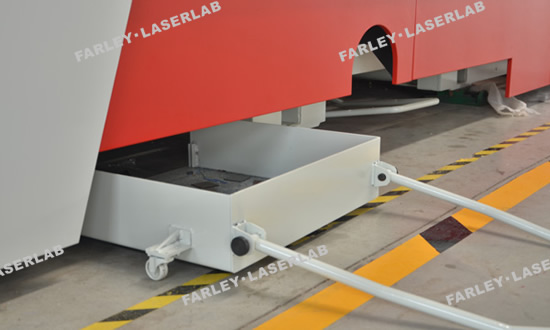

waste at the bottom of the trailer can be discharged wastes generated during the cutting process copyright huagong laser all, reproduced, please indicate the source. 。3 |

| About Cardofcom|Add to Favorites|Register Cardofcom.net|Proposed Feedback|Contact us |

| Cardofcom.net---Card of com at net |

| 版权所有 沧州双一商贸有限公司 冀ICP备16002221号 |